Smart Industrial Systems: Automation, IIoT, and Remote Management

Steve Maurer, IME

In the constantly changing view of industrial electrical systems, the surge of innovation isn’t just changing the game; it's rewriting the rulebook. From the factory floor to the remote control room, the integration of intelligent automation and the Internet of Things (IoT) is transforming how industries operate, maintain, and innovate their machine control systems.

This isn't just about efficiency or productivity anymore—it's about revolutionizing the very fabric of industrial operations in a way that was once relegated to the realms of science fiction.

But why does this matter? In industries where downtime is the arch-nemesis of profitability, the ability to predict, prevent, and respond to issues swiftly is vital. Intelligent automation, bolstered by the power of IIoT, offers just that: a promise of not only heightened efficiency but also unprecedented reliability and resilience.

This is a journey into the future of industrial electrical systems, where remote monitoring, predictive maintenance, and smart controls aren't just perks; they're essential components of a competitive strategy.

This isn't just about efficiency or productivity anymore—it's about revolutionizing the very fabric of industrial operations in a way that was once relegated to the realms of science fiction.

But why does this matter? In industries where downtime is the arch-nemesis of profitability, the ability to predict, prevent, and respond to issues swiftly is vital. Intelligent automation, bolstered by the power of IIoT, offers just that: a promise of not only heightened efficiency but also unprecedented reliability and resilience.

This is a journey into the future of industrial electrical systems, where remote monitoring, predictive maintenance, and smart controls aren't just perks; they're essential components of a competitive strategy.

Buckle up and let’s explore the smart industrial electrical systems cosmos.

The Integration of Intelligent Automation in Industrial Electrical Systems

Step into the loop of industrial electrical systems, and you'll find yourself in a world where intelligent automation isn't just a buzzword—it's the cornerstone of innovation. This isn't your grandfather's factory setup. It's a dynamic, interconnected ecosystem where machines and systems communicate, learn, and adapt.

But what exactly is intelligent automation? It's the fusion of technologies like artificial intelligence (AI), robotics, and machine learning, all working in concert to create systems that can think, act, and optimize operations with minimal human intervention.

Step into the loop of industrial electrical systems, and you'll find yourself in a world where intelligent automation isn't just a buzzword—it's the cornerstone of innovation. This isn't your grandfather's factory setup. It's a dynamic, interconnected ecosystem where machines and systems communicate, learn, and adapt.

But what exactly is intelligent automation? It's the fusion of technologies like artificial intelligence (AI), robotics, and machine learning, all working in concert to create systems that can think, act, and optimize operations with minimal human intervention.

Now, let's talk about the cool stuff—why this matters. Imagine a production line that self-adjusts in real-time to changes in demand, or a maintenance system that predicts failures before they happen. This is the power of intelligent automation. It's not just about making tasks easier; it's about making systems smarter, faster, and more reliable.

The benefits are clear: reduced downtime, lower operational costs, and an enhanced ability to respond to market changes swiftly and effectively.

But, as with any major innovation, there are hurdles to clear. Integrating these technologies into existing systems can be daunting. Compatibility, cybersecurity, and cost are just a few of the challenges companies face. Yet, the solution lies in strategic implementation—starting small, proving value, and scaling up.

The benefits are clear: reduced downtime, lower operational costs, and an enhanced ability to respond to market changes swiftly and effectively.

But, as with any major innovation, there are hurdles to clear. Integrating these technologies into existing systems can be daunting. Compatibility, cybersecurity, and cost are just a few of the challenges companies face. Yet, the solution lies in strategic implementation—starting small, proving value, and scaling up.

It's about choosing the right partners and technologies… and not being afraid to innovate.

The integration of intelligent automation into industrial electrical systems isn’t just a step forward; it's a leap into a future where industries are not just reactive but proactive. Where they don't just survive; they thrive.

The integration of intelligent automation into industrial electrical systems isn’t just a step forward; it's a leap into a future where industries are not just reactive but proactive. Where they don't just survive; they thrive.

Resilience and Reliability of Today's IIoT Machine Controls

IIoT takes the concept of connectivity and cranks it up several notches, creating a network of devices that can communicate, analyze, and make decisions in real-time. This isn't just about machines talking to each other; it's about creating a resilient and reliable ecosystem that can withstand the bumps and shocks of industrial operations.

But what makes IIoT machine controls stand out? First, it's their ability to anticipate and adapt. With real-time data streaming from every sensor, these systems can predict failures before they happen, allowing for preventative maintenance that keeps downtime to a bare minimum. It's like having a crystal ball, but instead of vague prophecies, you get actionable insights that keep things running smoothly.

It also means that reliability isn’t just a feature; it's a fundamental component. By leveraging cloud technologies and advanced analytics, IIoT systems ensure that operations can continue no matter what. This also enables rapid response to any issues, minimizing impact and restoring operations swiftly.

However, embracing IIoT doesn't come without its challenges. It requires a robust cybersecurity strategy to protect against threats in an ever-connected world. Yet, the benefits far outweigh the risks. By enhancing the resilience and reliability of machine controls, IIoT isn't just changing the game—it's setting a new standard for industrial operations.

In the end, IIoT machine controls represent a significant leap forward in our quest for industrial systems that are not just efficient, but virtually unshakeable. This is the future of industrial operations, where every machine isn’t just a cog in the machine but a smart, connected, and resilient part of a larger, more reliable whole.

Cool.

But what makes IIoT machine controls stand out? First, it's their ability to anticipate and adapt. With real-time data streaming from every sensor, these systems can predict failures before they happen, allowing for preventative maintenance that keeps downtime to a bare minimum. It's like having a crystal ball, but instead of vague prophecies, you get actionable insights that keep things running smoothly.

It also means that reliability isn’t just a feature; it's a fundamental component. By leveraging cloud technologies and advanced analytics, IIoT systems ensure that operations can continue no matter what. This also enables rapid response to any issues, minimizing impact and restoring operations swiftly.

However, embracing IIoT doesn't come without its challenges. It requires a robust cybersecurity strategy to protect against threats in an ever-connected world. Yet, the benefits far outweigh the risks. By enhancing the resilience and reliability of machine controls, IIoT isn't just changing the game—it's setting a new standard for industrial operations.

In the end, IIoT machine controls represent a significant leap forward in our quest for industrial systems that are not just efficient, but virtually unshakeable. This is the future of industrial operations, where every machine isn’t just a cog in the machine but a smart, connected, and resilient part of a larger, more reliable whole.

Cool.

Remote Monitoring and Maintenance of Machine Control Systems

Gone are the days when monitoring and maintaining industrial machinery required a constant physical presence. Welcome to the age of remote monitoring and maintenance—a game-changer in the world of machine control systems. This is where technology meets convenience, allowing for the oversight and upkeep of industrial operations from virtually anywhere in the world.

The value of this approach is multi-layered.

For starters, remote monitoring provides a continuous, real-time stream of data, offering insights into the performance and health of machinery that were previously impossible without being on-site. This means potential issues can be identified and addressed before they escalate into costly downtime.

Imagine being able to prevent a breakdown before it happens, saving time, resources, and a whole lot of headaches. That's the power of remote monitoring.

On the maintenance front, the benefits are equally compelling.

Remote maintenance capabilities allow for the adjustment, troubleshooting, and even some repair of systems without needing to physically touch the equipment. This not only reduces the need for frequent on-site visits, which can be costly and time-consuming but also enhances the responsiveness to issues, ensuring that operations are back up and running as quickly as possible.

But the real beauty of remote monitoring and maintenance lies in its ability to facilitate predictive maintenance strategies. By analyzing data trends over time, businesses can predict when a piece of equipment is likely to fail and intervene proactively. This shift from reactive to predictive maintenance can lead to significant cost savings, improved equipment lifespan, and enhanced operational efficiency.

In essence, the value of remote monitoring and maintenance of machine control systems cannot be overstated. It's transforming the landscape of industrial operations, offering unprecedented levels of oversight, efficiency, and reliability. As we move forward, this technology will continue to be a critical component in the toolkit of industries aiming to stay ahead in an increasingly competitive and technology-driven world.

Gone are the days when monitoring and maintaining industrial machinery required a constant physical presence. Welcome to the age of remote monitoring and maintenance—a game-changer in the world of machine control systems. This is where technology meets convenience, allowing for the oversight and upkeep of industrial operations from virtually anywhere in the world.

The value of this approach is multi-layered.

For starters, remote monitoring provides a continuous, real-time stream of data, offering insights into the performance and health of machinery that were previously impossible without being on-site. This means potential issues can be identified and addressed before they escalate into costly downtime.

Imagine being able to prevent a breakdown before it happens, saving time, resources, and a whole lot of headaches. That's the power of remote monitoring.

On the maintenance front, the benefits are equally compelling.

Remote maintenance capabilities allow for the adjustment, troubleshooting, and even some repair of systems without needing to physically touch the equipment. This not only reduces the need for frequent on-site visits, which can be costly and time-consuming but also enhances the responsiveness to issues, ensuring that operations are back up and running as quickly as possible.

But the real beauty of remote monitoring and maintenance lies in its ability to facilitate predictive maintenance strategies. By analyzing data trends over time, businesses can predict when a piece of equipment is likely to fail and intervene proactively. This shift from reactive to predictive maintenance can lead to significant cost savings, improved equipment lifespan, and enhanced operational efficiency.

In essence, the value of remote monitoring and maintenance of machine control systems cannot be overstated. It's transforming the landscape of industrial operations, offering unprecedented levels of oversight, efficiency, and reliability. As we move forward, this technology will continue to be a critical component in the toolkit of industries aiming to stay ahead in an increasingly competitive and technology-driven world.

Charting the Future: The Industrial Revolution Redefined

As we stand on the brink of a technological revolution in industrial electrical systems, the integration of intelligent automation, the resilience offered by IIoT machine controls, and the unparalleled convenience of remote monitoring and maintenance represent more than just advancements.

They symbolize a fundamental shift in how industries operate, maintain, and innovate. These aren't just tools or technologies; they’re the building blocks of a new industrial era where efficiency, reliability, and foresight define success.

As we stand on the brink of a technological revolution in industrial electrical systems, the integration of intelligent automation, the resilience offered by IIoT machine controls, and the unparalleled convenience of remote monitoring and maintenance represent more than just advancements.

They symbolize a fundamental shift in how industries operate, maintain, and innovate. These aren't just tools or technologies; they’re the building blocks of a new industrial era where efficiency, reliability, and foresight define success.

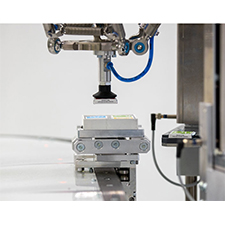

Photo courtesy of Schneider Electric