Building Resilience from the Foundation, Up, with ICF Construction

Chuck Ross

Exterior residential wall construction is receiving more attention these days, especially in areas now prone to dangerous weather conditions. Traditional wood-frame approaches can have difficulty withstanding extreme winds, flooding, and wildfires, and both building departments and home insurers are taking notice. Local building codes and insurance underwriters working in areas prone to such events are pushing for more resilient building technologies. Insulated concrete forms (ICFs) are one option for adding both resiliency and energy efficiency, but they do require electrical contractors to do their installation work a little differently.

ICFs are essentially rigid-foam sandwiches with a poured concrete center and metal rebar installed horizontally as reinforcement. The foam-based forms are put in place with plastic or metal spacers between them to create the opening needed for the poured concrete. Unlike traditional wood forms, the foam forms remain in place, providing efficiency-enhancing insulation. ICFs might just be used for a foundation, but they also can continue above-ground, creating exterior walls that – when paired with flame-resistant siding and roofing – can stand up to conditions that wood-frame construction can’t survive.

The challenge for contractors comes with the fact that these walls have no interior space for running wiring or installing outlet or switch boxes. Instead, they must carve out box openings and wiring channels from the form’s interior-facing foam layer. Box installation can be especially tricky with traditional products designed for stud walls and can require lining boxes up with the spacers for secure attachment.

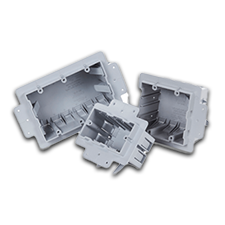

To address this installation chore, some manufacturers have come up with boxes specifically designed for ICF use. These boxes are fully flanged to keep boxes from twisting or sinking into the foam and can feature “teeth” that grip the box into place. Thanks to these features, the boxes can be installed wherever they’re needed, with drywall setbacks to create a professional appearance once finishes are in place.

ICFs are essentially rigid-foam sandwiches with a poured concrete center and metal rebar installed horizontally as reinforcement. The foam-based forms are put in place with plastic or metal spacers between them to create the opening needed for the poured concrete. Unlike traditional wood forms, the foam forms remain in place, providing efficiency-enhancing insulation. ICFs might just be used for a foundation, but they also can continue above-ground, creating exterior walls that – when paired with flame-resistant siding and roofing – can stand up to conditions that wood-frame construction can’t survive.

The challenge for contractors comes with the fact that these walls have no interior space for running wiring or installing outlet or switch boxes. Instead, they must carve out box openings and wiring channels from the form’s interior-facing foam layer. Box installation can be especially tricky with traditional products designed for stud walls and can require lining boxes up with the spacers for secure attachment.

To address this installation chore, some manufacturers have come up with boxes specifically designed for ICF use. These boxes are fully flanged to keep boxes from twisting or sinking into the foam and can feature “teeth” that grip the box into place. Thanks to these features, the boxes can be installed wherever they’re needed, with drywall setbacks to create a professional appearance once finishes are in place.

Photo courtesy of Kraloy Fittings