Mind the Gap: Air-Sealing Options for Exterior Wall Outlets

Chuck Ross

Residential energy use today accounts for about 20% of U.S. greenhouse gas emissions – though this figure varies widely by region and income level. Certainly, getting more of our energy from renewable resources can help reduce those emissions, but we also need to limit overall energy demand in order to meet the emissions cuts necessary to blunt climate change’s worst effects. That will require paying even more attention to limiting air infiltration – a big goal of the 2021 edition of the International Energy Conservation Code (IECC), which has added provisions electrical contractors need to know about when specifying outlet boxes for their next new construction or major renovation project.

The IECC and other building codes and standards have steadily increased requirements to reduce air infiltration over the last couple decades, and with good reason. Any opening in an exterior wall, whether it’s a full penetration, like a door or window, or partial, like an electrical box inserted into the interior side of an exterior wall, creates an opportunity for outside air to enter into the inside environment. This can make a furnace work harder in the winter and air conditioning to run longer in warmer months. Improved air and vapor barriers for exterior walls and better insulation in exterior wall cavities already have made a big difference in building energy use. Now codes are fine-tuning requirements to make the incremental improvements needed to reduce that demand even further.

In line with this effort, the 2021 IECC takes a closer look at electrical and communications boxes installed “between conditioned and unconditioned spaces.” This could mean a wall box on an exterior or garage wall, or a floor or ceiling box between the floor and basement or ceiling and attic. Now, installers are required to air-seal around these units to keep infiltration to specified limits.

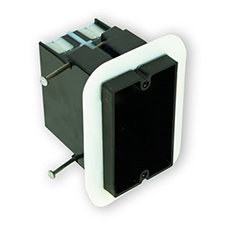

The updated language offers a time-saving product alternative to the tedious air-sealing process – new NEMA OS 4-rated outlet boxes. These boxes are designed for such applications without the need for added sealing. They can feature tapered flanges that create an air-tight seal against vapor barriers and drywall without needing additional adhesive or caulk. And self-sealing elastomeric knockouts allow seals to be maintained after wires are inserted – and also maintain that seal if wires are removed.

The IECC and other building codes and standards have steadily increased requirements to reduce air infiltration over the last couple decades, and with good reason. Any opening in an exterior wall, whether it’s a full penetration, like a door or window, or partial, like an electrical box inserted into the interior side of an exterior wall, creates an opportunity for outside air to enter into the inside environment. This can make a furnace work harder in the winter and air conditioning to run longer in warmer months. Improved air and vapor barriers for exterior walls and better insulation in exterior wall cavities already have made a big difference in building energy use. Now codes are fine-tuning requirements to make the incremental improvements needed to reduce that demand even further.

In line with this effort, the 2021 IECC takes a closer look at electrical and communications boxes installed “between conditioned and unconditioned spaces.” This could mean a wall box on an exterior or garage wall, or a floor or ceiling box between the floor and basement or ceiling and attic. Now, installers are required to air-seal around these units to keep infiltration to specified limits.

The updated language offers a time-saving product alternative to the tedious air-sealing process – new NEMA OS 4-rated outlet boxes. These boxes are designed for such applications without the need for added sealing. They can feature tapered flanges that create an air-tight seal against vapor barriers and drywall without needing additional adhesive or caulk. And self-sealing elastomeric knockouts allow seals to be maintained after wires are inserted – and also maintain that seal if wires are removed.

Photo courtesy of Allied Moulded Products