Intermediate Metal Conduit: A Practical Guide for Electrical Contractors

Steve Maurer, IME

As you know intimately, conduits are tubing systems that safeguard and guide wiring within a building or structure. Three types you've likely used —Intermediate Metal Conduit (IMC), Rigid Metal Conduit (RMC), and Electrical Metallic Tubing (EMT)— are steel-based conduits, each with its unique attributes.

- IMC is a conduit variety primarily found in industrial and commercial setups. Introduced in the 1970s, IMC serves as a lighter, more user-friendly substitute for RMC. It's thicker than EMT but not as heavy as RMC, making it versatile for different weather conditions and usable as structural support for electric devices.

- RMC is a heavy-duty conduit composed of either galvanized steel or stainless steel, offering high-level protection for electrical wires. However, due to its robust nature, it's tougher to handle and install than IMC or EMT, making it the most costly option.

- EMT, often referred to as "thin-wall," is the most lightweight and economical conduit among these. It is typically used in commercial and some industrial settings, crafted from thin steel, and is easy to manipulate for complex installations. But, it doesn't match the durability of IMC or RMC and cannot offer structural support. EMT is usually used indoors and isn't recommended for extreme or corrosive environments unless adequately shielded or made of corrosion-resistant materials.

The conduit choice mainly hinges on job specifics like the installation environment, wiring type, and project's physical demands.

Electrical design prioritizes efficiency, safety, and cost-effectiveness. The Intermediate Metal Conduit (IMC) meets these criteria, offering unique advantages for electrical professionals.

Electrical design prioritizes efficiency, safety, and cost-effectiveness. The Intermediate Metal Conduit (IMC) meets these criteria, offering unique advantages for electrical professionals.

IMC: Efficiency Meets Durability

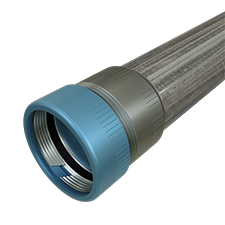

Manufactured from premium, hardened steel, IMC stands as a conduit that offers substantial protection and enduring value for electrical raceway systems. Its blend of durability and convenience sets it apart. Although it has the same outer diameter as RMC, the thinner wall gives it a larger inner diameter, making wire pulling easier.

Importantly, certain IMC products like the Super Kwik-Couple IMC feature factory-installed couplings. This characteristic removes the need to purchase, store, and install separate couplings – a process that can be both expensive and time-consuming. They sometimes are designed to tighten without turning the conduit, thereby speeding up the installation process and reducing costs.

Importantly, certain IMC products like the Super Kwik-Couple IMC feature factory-installed couplings. This characteristic removes the need to purchase, store, and install separate couplings – a process that can be both expensive and time-consuming. They sometimes are designed to tighten without turning the conduit, thereby speeding up the installation process and reducing costs.

Versatility: NEC-Approved

The National Electrical Code (NEC) permits the use of IMC across all applications where Rigid Metal Conduit (RMC) is typically used. Whether your project involves installation in damp areas or embedded within concrete, IMC serves as a suitable choice, provided all associated supports, bolts, straps, and screws are corrosion-resistant. This versatility, combined with strict safety adherence, makes IMC a practical choice for various project circumstances.

Grounding and Fire Safety

Beyond cable protection, IMC also excels as an effective grounding conductor, as recognized in Article 250 of the NEC. Fire safety is another area where IMC stands out; it conforms to the Underwriters Laboratories (UL) Safety Standard 1242 and is considered non-combustible, making it suitable for penetrating firewalls. These safety features further enhance its overall project utility.

Beyond cable protection, IMC also excels as an effective grounding conductor, as recognized in Article 250 of the NEC. Fire safety is another area where IMC stands out; it conforms to the Underwriters Laboratories (UL) Safety Standard 1242 and is considered non-combustible, making it suitable for penetrating firewalls. These safety features further enhance its overall project utility.

An Environmentally Conscious Choice: IMC

Beyond its functional benefits, IMC presents an environmentally conscious option. Often produced from a mild steel strip, IMC incorporates a certain amount of recycled steel depending on the specific manufacturing process. Although it is lighter than rigid steel conduit, IMC does not compromise on the protection it offers to conductors and cables, even in areas that might be exposed to severe physical damage.

Beyond its functional benefits, IMC presents an environmentally conscious option. Often produced from a mild steel strip, IMC incorporates a certain amount of recycled steel depending on the specific manufacturing process. Although it is lighter than rigid steel conduit, IMC does not compromise on the protection it offers to conductors and cables, even in areas that might be exposed to severe physical damage.

Conclusion

Given its combination of functional and environmental advantages, IMC makes a compelling case for inclusion in the electrical contractor's toolkit. Its promise of efficiency, durability, and versatility – all while being environmentally friendly – adds significant value. However, remember that local codes and the authority having jurisdiction (AHJ) may have differing guidelines, so always verify your planned installation with the local AHJ prior to proceeding.

By giving electrical contractors another option to deliver safe, cost-effective, and efficient solutions, IMC could well become a go-to resource for many professionals in the field.

Given its combination of functional and environmental advantages, IMC makes a compelling case for inclusion in the electrical contractor's toolkit. Its promise of efficiency, durability, and versatility – all while being environmentally friendly – adds significant value. However, remember that local codes and the authority having jurisdiction (AHJ) may have differing guidelines, so always verify your planned installation with the local AHJ prior to proceeding.

By giving electrical contractors another option to deliver safe, cost-effective, and efficient solutions, IMC could well become a go-to resource for many professionals in the field.

Photo courtesy of Atkore