PREVENT ELECTRICAL SHOCK IN COMMERCIAL AND INDUSTRIAL APPLICATIONS

Next-Level Shock Protection

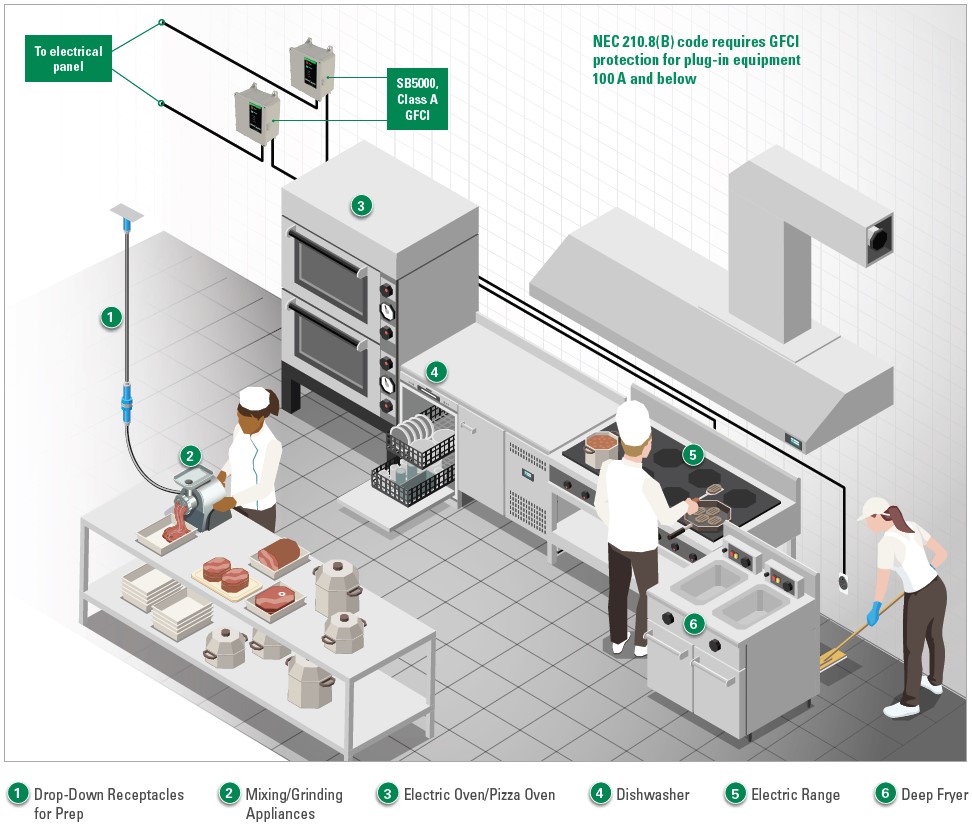

In food and beverage processing and commercial kitchen applications, combining wet environments and stainless steel equipment creates a situation where shock can occur.

Electric ranges and other equipment must be movable to meet sanitation standards, requiring plugs. Flexible cords can wear over time, increasing a worker’s risk of electrical shock.

The National Electrical Code (NEC) now requires a ground-fault circuit interrupter (GFCI). The Littelfuse SB5000 Shock Block protects employees from electric shock. It ensures code compliance for 208 V three-phase applications up to 100 A.

Learn how we have helped national fast-food chains with next-level shock protection, protecting personnel and businesses.

Our 80 A and 100 A Models Available Now

The Shock Block SB5100 is a personnel protection device designed to meet the requirements for special-purpose GFCIs defined by UL 943C.

How to Meet GFCI requirements for Commercial Kitchens

Common 208 V Appliances in Commercial Kitchens

Industrial Application - Food and Beverage Processing

The NEC 210.8[B] code requires GFCI protection for any plug and cord equipment that is 208 V, 3-phase and 100 A or below. Plug-in equipment such as dryers, mixers, cutting equipment, and conveyers fall into this category and must be protected with a GFCI. The Littelfuse SB5000, with a stainless steel enclosure, will meet this code requirement for your facility, from 208 V to 600 V. Personnel protection for all situations.

Commercial Construction, Water/Wastewater, Mining, and Oil & Gas

Special purpose GFCIs are required in industrial facilities and construction to meet the requirements defined by UL 943C. Class C GFCIs are intended to be used on three-phase systems where the line-to-line voltage is 480 V or less with a trip level of 20 mA, while Class D GFCIs are intended to be used on 600 V systems. The Industrial Shock Block includes an automatic self-test feature and is compliant to the UL 1998 Software in Programmable Components standard.

Features

The Littelfuse Shock Block SB5000 offers features that:

Meets GFCI requirements of NEC 210.8 (B) for large electrical equipment in commercial kitchens

Reduces unnecessary tripping by taking advantage of advanced filtering technology

Includes NEMA 4X and IP69K enclosure ratings for all food-preparation environments

The Shock Block SB5000 is available in 32, 60, 80 and 100 amp models

FAQs

For the Shock Block Resource Kit, Fill Out the Form Below.

Questions? Reach out.

We want to hear from you. Once submitted, our engineering team will be in touch with you shortly.