Increase Profit Margins Using Labor-saving Cable and Data Wiring

Steve Maurer, IME

Every electrical contractor I know is in the business to make a profit. One of the only ways to increase your profits over time is to take on more and larger electrical projects. The more work, the more money… most of the time.

But, taking on more projects usually means adding staff. Your crew needs to be bigger to handle the load.

However, larger crews means higher labor costs. And if you don’t have enough team members, overtime pay can take a huge chunk out of your profits.

But there could be a way to raise your profit margin without having to significantly reduce your labor force. If you could make your installations and renovations easier, with the potential to do more with fewer workers on each jobsite, that might allow you do take on more and bigger projects without breaking the bank.

How can you do that?

Well, in this article we’ll talk about just one aspect that might save money. Labor saving products used in cable and data wiring could be the ticket to higher profitability.

We’ll briefly cover several types of products:

Determining whether they fit your business is your call.

Pre-terminated Cable Systems

One of the most labor-intensive tasks in any type of electrical work is terminating and landing cable. When it comes to data and some low power connections, the work is quite tedious.

You have the schematics and blueprints. You know the length of the cable runs. So, why not consider pre-terminated cable systems?

Pre-terminated cables are designed with connectors already installed on one or both ends, which offers a distinct advantage by eliminating the need for individually wiring each connection point. This feature significantly speeds up the installation process compared to the traditional method of running individual wires and attaching connectors manually.

Among the common types of pre-terminated cables are Ethernet, HDMI, USB, and various power cables. The use of pre-installed connectors not only ensures a secure and reliable connection but also helps in eliminating potential wiring errors that might occur during manual installation. Most are pre-tested at the manufacturer, ensuring correct connections.

This makes pre-terminated cables an excellent choice for ensuring both efficiency and reliability in electrical setups.

Modular Wiring and Wiring Harnesses

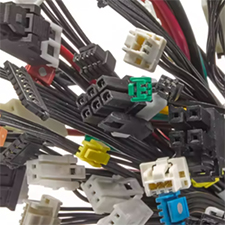

Modular wiring systems are designed to facilitate quick and tool-free connections between components using standardized plugs and sockets. This design allows for a faster and more flexible installation process compared to traditional hardwired connections. To ensure proper mating, modular systems often employ color-coded or keyed connectors, which help prevent incorrect connections.

These systems are particularly adaptable, allowing for easy reconfiguration or expansion of the wiring system as needs change. Common applications of modular wiring include lighting, HVAC, and building automation systems, highlighting their versatility and effectiveness in a variety of settings.

I’ve used modular cables for installing ceiling troffers in large areas like breakrooms. Correct connections, including the ground wires, are almost guaranteed.

Wireless Control Systems

The path from Point A to Point B doesn’t always need to be a cable.

Wireless technologies such as Bluetooth, Wi-Fi, and proprietary RF protocols revolutionize the control of appliances and devices by eliminating the need for physical wiring. This feature significantly simplifies the installation process by removing the necessity to run cables between the control point and the appliance.

Wireless systems can be powered in various ways, including batteries or energy harvesting techniques, which allow them to operate independently of a wired power source. Additionally, the flexibility of wireless systems enables easy reconfiguration and versatile placement of controls.

Common uses for wireless systems include applications in lighting, HVAC, security, and home automation, demonstrating their broad utility and adaptability in modern technological environments.

Hybrid Cables

These… I love. How many times have you had to run different types of cables to the same location from the same origin point? More than you’d like to remember. But hybrid cables may be the answer to that challenge.

Hybrid cables are innovative solutions that integrate multiple types of conductors, such as power, data, and control, into a single cable. This integration significantly reduces the number of individual wires that need to be routed, thereby streamlining the installation process.

This makes them particularly advantageous in environments where space is at a premium and neatness is crucial, compared to traditional methods where separate cables are used for each function.

In fact, in various processing plants where cleanliness is crucial, hybrid cable can cut down on the crud.

Direct Burial Cabling

Direct burial cables are specifically designed for underground installation without the need for conduits or raceways, simplifying the installation process and reducing the need for additional labor and materials typically required for a protective wiring infrastructure.

These cables feature tough, waterproof jackets and are specifically rated for underground use, ensuring durability and protection against environmental elements. Commonly used in outdoor applications, direct burial cables are ideal for landscape lighting, irrigation controls, and power distribution.

By eliminating the need for conduits, direct burial not only streamlines the installation process but also significantly lowers the overall costs associated with wiring in outdoor environments.

Make sure you’re following all Code requirements and not running afoul of any specific regulations.

The Bottom Line to Using Specialized Data and Cable Systems

In summary, these labor-saving products significantly streamline the complexity and time demands of electrical wiring and installation. By simplifying connections, reducing the number of individual wires, and eliminating the need for additional infrastructure, they lower the labor costs associated with electrical projects.

This efficiency not only speeds up the installation process but also makes it more cost-effective, benefiting both contractors and their clients. This streamlined approach not only enhances efficiency but also results in financial savings, making these solutions highly strategic for everyone involved.

But, taking on more projects usually means adding staff. Your crew needs to be bigger to handle the load.

However, larger crews means higher labor costs. And if you don’t have enough team members, overtime pay can take a huge chunk out of your profits.

But there could be a way to raise your profit margin without having to significantly reduce your labor force. If you could make your installations and renovations easier, with the potential to do more with fewer workers on each jobsite, that might allow you do take on more and bigger projects without breaking the bank.

How can you do that?

Well, in this article we’ll talk about just one aspect that might save money. Labor saving products used in cable and data wiring could be the ticket to higher profitability.

We’ll briefly cover several types of products:

- pre-terminated cable systems

- modular wiring

- wireless control systems

- hybrid cables

- direct burial

Determining whether they fit your business is your call.

Pre-terminated Cable Systems

One of the most labor-intensive tasks in any type of electrical work is terminating and landing cable. When it comes to data and some low power connections, the work is quite tedious.

You have the schematics and blueprints. You know the length of the cable runs. So, why not consider pre-terminated cable systems?

Pre-terminated cables are designed with connectors already installed on one or both ends, which offers a distinct advantage by eliminating the need for individually wiring each connection point. This feature significantly speeds up the installation process compared to the traditional method of running individual wires and attaching connectors manually.

Among the common types of pre-terminated cables are Ethernet, HDMI, USB, and various power cables. The use of pre-installed connectors not only ensures a secure and reliable connection but also helps in eliminating potential wiring errors that might occur during manual installation. Most are pre-tested at the manufacturer, ensuring correct connections.

This makes pre-terminated cables an excellent choice for ensuring both efficiency and reliability in electrical setups.

Modular Wiring and Wiring Harnesses

Modular wiring systems are designed to facilitate quick and tool-free connections between components using standardized plugs and sockets. This design allows for a faster and more flexible installation process compared to traditional hardwired connections. To ensure proper mating, modular systems often employ color-coded or keyed connectors, which help prevent incorrect connections.

These systems are particularly adaptable, allowing for easy reconfiguration or expansion of the wiring system as needs change. Common applications of modular wiring include lighting, HVAC, and building automation systems, highlighting their versatility and effectiveness in a variety of settings.

I’ve used modular cables for installing ceiling troffers in large areas like breakrooms. Correct connections, including the ground wires, are almost guaranteed.

Wireless Control Systems

The path from Point A to Point B doesn’t always need to be a cable.

Wireless technologies such as Bluetooth, Wi-Fi, and proprietary RF protocols revolutionize the control of appliances and devices by eliminating the need for physical wiring. This feature significantly simplifies the installation process by removing the necessity to run cables between the control point and the appliance.

Wireless systems can be powered in various ways, including batteries or energy harvesting techniques, which allow them to operate independently of a wired power source. Additionally, the flexibility of wireless systems enables easy reconfiguration and versatile placement of controls.

Common uses for wireless systems include applications in lighting, HVAC, security, and home automation, demonstrating their broad utility and adaptability in modern technological environments.

Hybrid Cables

These… I love. How many times have you had to run different types of cables to the same location from the same origin point? More than you’d like to remember. But hybrid cables may be the answer to that challenge.

Hybrid cables are innovative solutions that integrate multiple types of conductors, such as power, data, and control, into a single cable. This integration significantly reduces the number of individual wires that need to be routed, thereby streamlining the installation process.

Common types of hybrid cables include combinations like power/data, power/control, and multi-conductor cables. By consolidating various functionalities into one cable, hybrid cables help minimize clutter and simplify cable management.

In fact, in various processing plants where cleanliness is crucial, hybrid cable can cut down on the crud.

Direct Burial Cabling

Direct burial cables are specifically designed for underground installation without the need for conduits or raceways, simplifying the installation process and reducing the need for additional labor and materials typically required for a protective wiring infrastructure.

These cables feature tough, waterproof jackets and are specifically rated for underground use, ensuring durability and protection against environmental elements. Commonly used in outdoor applications, direct burial cables are ideal for landscape lighting, irrigation controls, and power distribution.

By eliminating the need for conduits, direct burial not only streamlines the installation process but also significantly lowers the overall costs associated with wiring in outdoor environments.

Make sure you’re following all Code requirements and not running afoul of any specific regulations.

The Bottom Line to Using Specialized Data and Cable Systems

In summary, these labor-saving products significantly streamline the complexity and time demands of electrical wiring and installation. By simplifying connections, reducing the number of individual wires, and eliminating the need for additional infrastructure, they lower the labor costs associated with electrical projects.

This efficiency not only speeds up the installation process but also makes it more cost-effective, benefiting both contractors and their clients. This streamlined approach not only enhances efficiency but also results in financial savings, making these solutions highly strategic for everyone involved.

Photo courtesy of Molex